Transport Wall on Vault Side

Repair of

Gary Lauten, August 8, 2003

OVERVIEW

There are 2 Beam Stops located behind the wall on the vault side.† These are Critical Devices.† Typically the area at this end of Transport is a High Radiation Area, with rates of about 125 mrem an hour at 1 foot on 8/8/03.† The beamline in this region is overhead.

The wall is constructed using aluminum panels, attached with RTV and sheet metal screws.†

The beam stops are located under the AP2 and AP3 beamlines in Transport, just behind the wall.† Access to these beam stops is gained by removing a panel below the beamline.

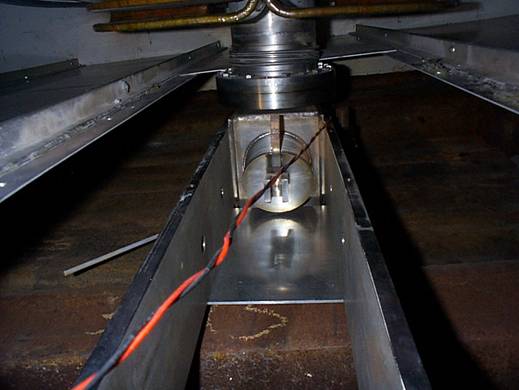

Once the panel is removed, workers are able to reach inside and work on the beam stop motors, actuators, and wiring.† The beam stop motor assembly is small enough that a person could handle it.† See Figure 1.

Figure 1:† Notice the panel removed from the wall section below the AP2 beamline.† The object you can see

inside the opening is the beam stop motor assembly.

Figure 2:† In this photo, the motor assembly has been removed and the electrical device you see is the board for

The limit switches.† There are 4 limit switches total, a pair on each side.† There is a upper (beam stop IN) limit position, and a lower (beam stop OUT) position.†

Figure 3:† Looking up into the opening: beam stop sans motor drive assembly.† Notice the overhead beam line to orient yourself.

Figure 4:† Motor drive assembly.

RADIOLOGICAL COVERAGE

OF THIS WORK

Summary of Job done

1.†††††††† When this

job was done on

2.†††††††† The contamination level inside the wall on the motor assembly was about 100 ccpm.

3.†††††††† Grab air sample taken immediately after opening the panel was 80 cpm on an E140N, which converted to about 1 x 10-9 uCi/ml of airborne radioactivity.† This level was below the 1 x 10-8 uCi/ml limit for grab sample air (RP Form 25).

4.†††††††† Job took about 4 hours to do, with about 3 hours of prep time.† Workers had to access the motor assembly twice to get it to work properly.

How to Cover these

Jobs (What we need to do and things to think about)

1.†††††††† The first thing we need to do is

contact a FESS engineer (at this time is Cedric Madison) and have him turn off

the AP0 Building SUPPLY air fan

(this fan overpressures the building) and the AP0 Vault SUPPLY fan (overpressures the vault).† The reason we do this is as a precaution to

reduce the air flowing downward into the vault region and blowing back out

through the Transport side when a wall panel is removed.† We want to minimize the potential for

airborne radioactivity to blow out through openings on the Transport wall where

workers are located.† Cedric is able to

control these fans remotely.† When we did

this job on

2.†††††††† When personnel have a Transport key in their possession, this inhibits several CDC devices, including F17 and MHV100 and 200.† It is not possible to get a permit to run beam down the Pretarget and Prevault beamlines.

3††††††††† The FIRST thing we do when a wall panel comes off is TAKE A GRAB AIR SAMPLE with the High Vol air sampler and determine if the air is safe as per RP Form 25.† Normal Radiation Safety job coverage after this point.† Perform rad surveys as needed and have a pre-job planning meeting.† Workers need to understand what they need to do.† As usual, our function is to minimize any loitering in a high rad area, etc.† Most of the time when a device such as this fails, people have no idea exactly what the problem is, so expect that there will be some preliminary theories and diagnostic work that has to be done on the fly.† Expect low level contamination inside the wall, but we need to check.

4.†††††††† When workers are done, make sure they put the wall back together and use RTV to seal the panel.† We donít want any air seeping back through when we run beam.

5.†††††††† Even with the building and vault supply fans OFF, you could still feel cooler air moving out from the opening in the wall.† Weíve opened this wall twice in last 10 years, and both times you could feel this cooler air moving out.† This is why we take a grab air sample, to make sure there isnít a concern with airborne radioactivity.† We donít expect it, but we need to be check it.

6.†††††††† On

END†